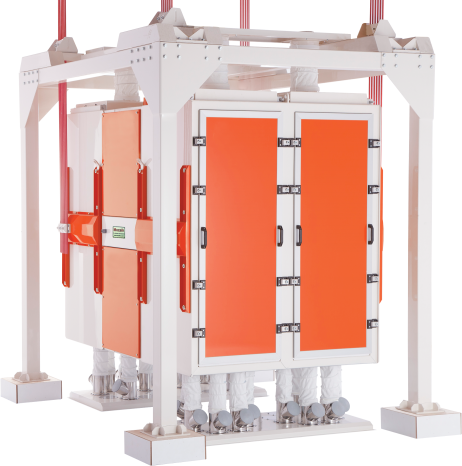

The control sieve is placed just before bagging the flour in order to remove possible foreign materials that have entered to the system and is used for precise final sifting of the flour.

Depending on the capacity of the factory, it is manufactured with 2 or 4 passages and 12-16-20 sieve boxes in each compartment.

| Model Modele |

Number of Section Nombre De Compar timens | A | Measures (mm) Dimensions (mm) B C (Min) |

D | Number Of Sieves Per Section Nombre De Tamis Par Compar- timents | Total Height Of Sieves Hauteur Tamissage (cm) |

Approximate Sifting Area (m^2) Surface Approximative De Tamisage W Type / Modele N Type / Modele Max Min Max Min |

Engine Speed (Rpm) Vitesse Moteur | Machine Speed (Rpm) Vitesse De La Machine | Working Engine kw Circle Poissance Diameter Moteur (mm) Diametre De Poulie |

Approximate Weight (Kg) Poids Approximative |

|||||

| GM 4/20 | 4 | 1500 | 1223 | 2795 | 1550 | 20-16 | 139 | 28,27 | 22,62 | 22,80 | 18,24 | 1000 | 245 | 3 | 65 | 2360 |

| GM 4/16 | 4 | 1500 | 1073 | 2645 | 1250 | 16-12 | 109 | 22,62 | 16,96 | 18,24 | 13,68 | 1000 | 245 | 3 | 65 | 2070 |

| GM 4/12 | 4 | 1500 | 923 | 2495 | 950 | 12-8 | 79 | 16,96 | 11,31 | 13,68 | 9,12 | 1000 | 245 | 3 | 65 | 1750 |

| GM 2/20 | 2 | 1500 | 1223 | 2795 | 1550 | 20-16 | 139 | 14,14 | 11,31 | 11,40 | 9,12 | 1000 | 245 | 2,2 | 65 | 1650 |

| GM 2/16 | 2 | 1500 | 1073 | 2645 | 1250 | 16-12 | 109 | 11,31 | 8,48 | 9,12 | 6,84 | 1000 | 245 | 2,2 | 65 | 1350 |

| GM 2/12 | 2 | 1500 | 923 | 2495 | 950 | 12-8 | 79 | 79 | 5,65 | 6,84 | 4,56 | 1000 | 245 | 2,2 | 65 | 1090 |